Uncategorized

The Perils of Firing a Kiln

For the next couple of weeks, I will take a break from the Marketing and Selling theme and focus on some significant events that occurred during the 1980s

Making Pottery for the Papal Mass in 1987

Several things happened in the 1980s that challenged me; one of those nearly killed me. In 1987, the Catholic archdiocese of south Texas commissioned to make the pottery for the Papal Mass held in San Antonio on September 13th that year. It was a large order with 1500 Ciborium, Chalice and Paten sets for the attending bishops, 4 huge covered jars similar in shape to the Ciborium to put any unused host in after serving everyone, and a bowl and pitcher set for the Pope to wash his hands. Just producing this amount of pottery for one order was a new experience, and I had to make some changes in how I did things to get the order done in time.

The Kiln Design

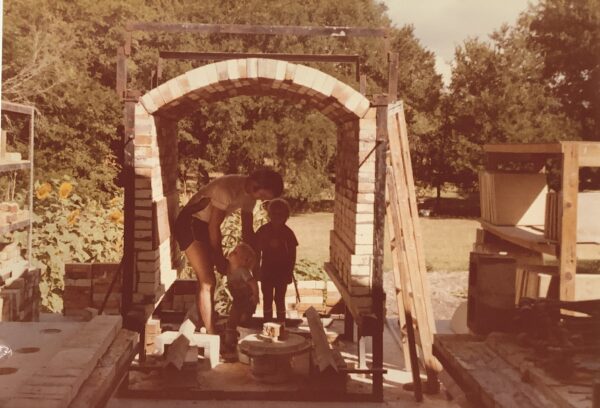

Notice the angle iron going into the kiln shell and the kiln car bed to the left and right.

When I built my kiln, I set up a two-car system. The cars had been part of the kiln that I purchased when I purchased some pottery equipment in the late 1970s. That kiln was designed with a car entering from each end. The kiln cars had v-grove wheels designed to roll on the edge of a length of 3” X 3” angle iron. To incorporate the two kiln cars in my new kiln, I built a track that was set perpendicular to the kiln and then put v-groove wheels on the track that the kiln cars set on. We could load one car with shelves and pottery while the other load was firing, and when the pottery was cool, it could be rolled out of the kiln and then pushed aside. The unfired load pushed in front of the kiln, the car rolled into the kiln, the door closed, and the next firing begun. I built the kiln about nine years before this, but I had never put the extra car into use. As the deadline for the order came near, I began to employ the extra kiln car. I set an aggressive twenty-four-hour firing schedule. It was risky because I had to pull the car from the kiln when the ware was still at about 700°, which could potentially have caused the pottery to suffer some thermal shock. Pieces could have cracked, or glaze shivered off the pottery when exposed to the cooler outside air.

Firing a Kiln Load Everyday

I don’t remember why I tried it, but it worked. Each evening about 5:00, I would open the kiln, pull out the car and shove the other car in and light the kiln. The heat from the previous firing helped move the subsequent firing along rapidly. My glazes mature at about 2400°, so the kiln had to reach that temperature about 10:00 AM the next day to begin cooling to be in the 700° range at 5:00 PM.

All Is Going Well

The firing schedule was working well, and I was making significant progress firing all the Papal Mass pottery. One evening in early August, I went out to change out the kiln cars for the next firing…..

To Be Continued